Technology

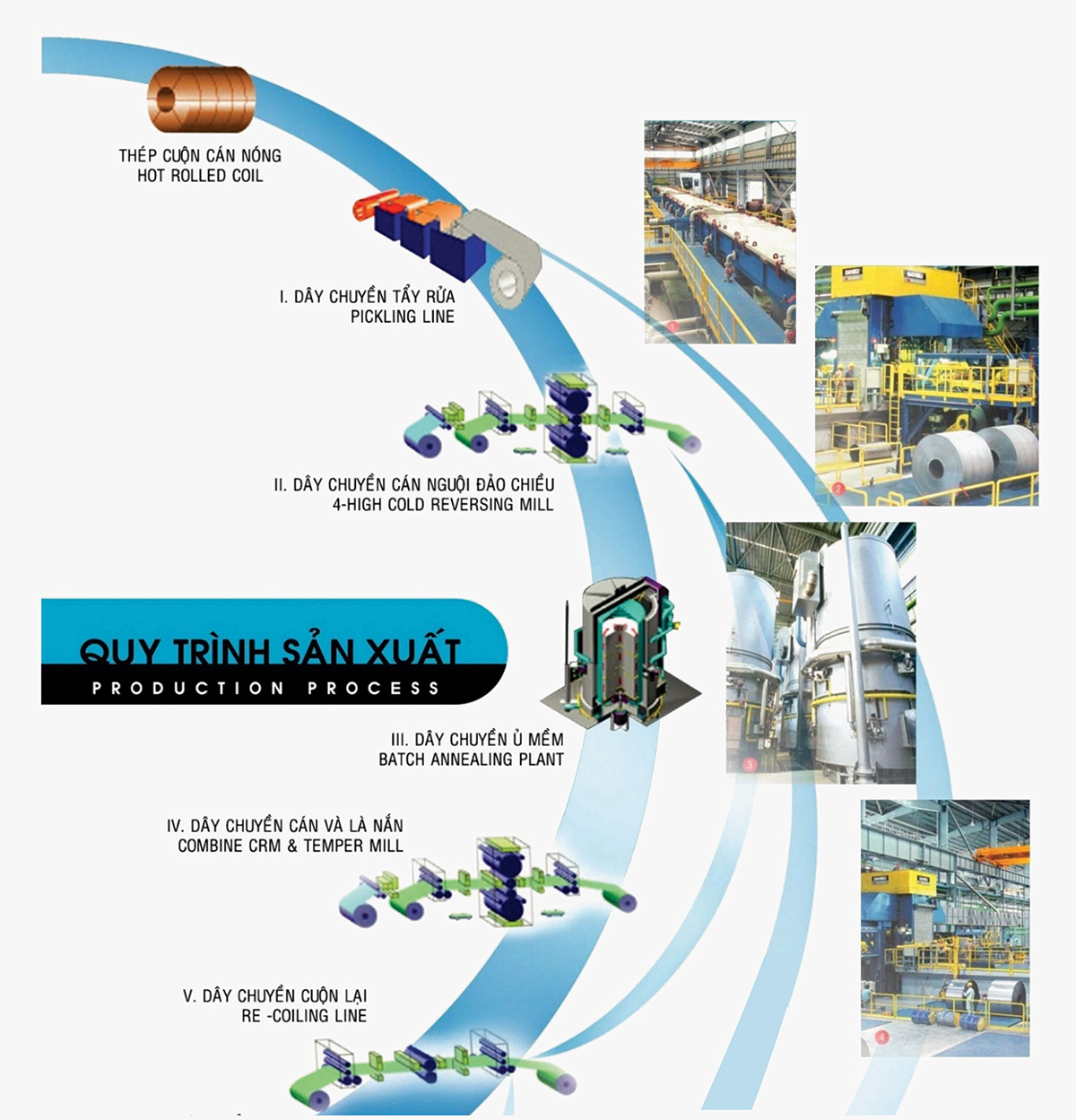

The production system of PFS follows the advanced 4-hi rolling technology of Danieli (Italy) with the operation process through 5 lines: Pickling Line; Cold Reversing Mill; Batch Annealing; Cold Reversing Mill and Temper Mill; Recoiling Line. The design capacity is 405,000 tons/year, including products: Soft Cold Rolled coil (Annealed coil), Full Hard Cold Rolled Coil (Full hard coil) and Pickled Coil (Pickled and oiled coil) according to JIS standards of Japan, DIN of Europe and ASTM of America.

Tiếng Việt

Tiếng Việt